Research and Development

Forward-looking mobility solutions with brand-defining products and services would be unthinkable without innovation. This makes our research and development work essential for sustainably increasing the value of the Company.

Together with our Group brands, we have launched measures based on our future program TOGETHER 2025+ to link development activities across the Group. At the heart of this is an efficient, cross-brand development alliance characterized by a close network of our experts, collaboration on an equal footing, an innovative working environment and the pooling of development activities. The aim is to make use of synergy effects across the Group and act as a role model for the environment, safety and integrity. The development alliance plays a major part in driving the Volkswagen Group’s transformation and helping to make it fit for the future.

In view of this strategic focus, we concentrated in the reporting period on continuing to develop forward-looking mobility solutions, establishing technological expertise to strengthen our competitiveness, expanding our range of products and services and improving the functionality, quality, safety and environmental compatibility of our products and services.

We use a strategic indicator in Europe and the United States to evaluate the effectiveness of our measures to reduce CO2 emissions when driving:

- CO2 fleet emissions. The Volkswagen Group’s new passenger car fleet in the EU (excluding Lamborghini and Bentley) emitted an average of 99.9 g CO2/km1 (NEDC) in the reporting period in accordance with the statutory measurement bases, thus down 20% on the prior-year figure. The CO2 pool established together with other manufacturers fell just 0.8 g CO2/km short of its target. Owing to delays in product launches and contrary to the original planning, it was not possible to achieve the target despite substantial improvements compared with 2019. As small volume manufacturers, the Lamborghini and Bentley brands each have an independent fleet for the purposes of European CO2 legislation and were both above their individual targets. In the United States, the regulation of fleet emissions is different to that in Europe, for example in terms of the underlying test process, the period of evaluation, which corresponds to the model year of the vehicles rather than the calendar year, and the period for compensating for any breaches of CO2 limits, which comprises three model years. In fiscal year 2020, we complied with the regulations that apply to our greenhouse gas account in the United States, subject to any alternative notification by the authorities.

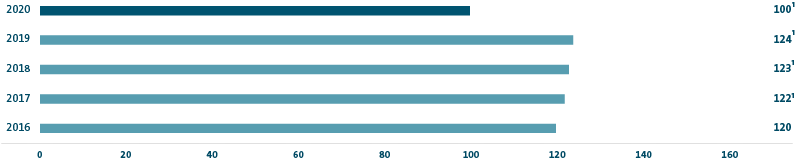

CO2 EMISSIONS OF THE VOLKSWAGEN GROUP’S EUROPEAN (EU27+3) NEW PASSENGER CAR FLEET

in grams per kilometer (NEDC)

Fuel and drivetrain strategy

With a view to the legal regulations on emissions, we are currently developing a forward-looking vehicle and drivetrain portfolio: we have set ourselves the objective of increasing drive system efficiency with each new model generation – irrespective of whether it is a combustion engine, a hybrid or a purely electric drive system. The Volkswagen Group closely coordinates technology and product planning with its brands so as to avoid breaches of fleet fuel consumption limits, since these would entail substantial excess emissions premiums. Around one in five new Volkswagen Group vehicles worldwide is to have a purely electric drive by the year 2025; depending on market development, this could be over two million electric vehicles a year. As part of our electrification campaign, we aim to offer our customers worldwide around 70 completely battery-electric vehicles by 2030, of which production of approximately 20 models has already started. In addition, a total of around 60 hybrid models are planned by the end of the decade, just over half of which are already in production. By 2030, the Volkswagen Group aims to have electrified its entire model portfolio – from high-volume models to premium vehicles. This will mean offering at least one electric version – battery electric or hybrid vehicles – of each of our passenger car models across all Group brands. To this end, in addition to the Modular Electric Drive Toolkit (MEB), we are also developing an all-electric platform for our premium and sports brands – the Premium Platform Electric (PPE).

The Volkswagen Group is committed to achieving the goals of the Paris Agreement on climate change and intends to become a net-carbon-neutral company by 2050.

To offer sustainable, affordable mobility in the future for as many people around the world as possible, we offer a range of drivetrains with a focus on electrification. From today’s perspective, conventional combustion engines look set to continue to make up the lion’s share of drive technology in the coming years. In the interest of using resources responsibly, it is therefore essential to further enhance this engine segment and systematically consolidate it for specific markets. Powertrain measures such as significantly more sophisticated exhaust gas purification or mild hybridization of our vehicles, as well as vehicle measures such as optimized aerodynamics or reduced rolling resistance will be necessary to fulfill future emissions standards. With the new Golf 8 we offer more efficient and more sustainable mobility in the volume segment: The Golf’s new petrol mild hybrid drivetrain significantly reduces fuel consumption compared to its predecessor.

It is more important to us than ever to rigorously pursue our modular approach. We are reducing the number of individual modules so that we can make a large product portfolio economically viable. For example, we aim to reduce the number of versions of conventional combustion engines in the Group by more than a third in the long term. This will create capacity for the development and production of new hybrid and electric drives.

Life cycle engineering and recycling

Technological innovation for reducing fuel consumption is not enough on its own to minimize the effect of vehicles on the environment. We consider the environmental impact we cause throughout the entire life cycle and at all stages of the value chain. This includes the manufacturing process with the associated extraction of raw materials, the production of materials, the processes at our suppliers and our own production operations at our sites, the use phase with the resulting vehicle emissions and the necessary supply of fuel, and ultimately the recycling of the vehicle at the end of its life cycle. We identify the stages of the life cycle at which improvements will have the greatest effect and develop appropriate solutions. We call this life cycle engineering. Recycling, for example, is an important means of reducing environmental impact and conserving resources. We therefore already take the recyclability of the required materials into consideration when developing new vehicles, use high-quality recycled material and avoid pollutants. Under the European Directive on end-of-life vehicles, passenger cars and light commercial vehicles must be 85% recyclable and 95% recoverable. Our vehicles registered in Europe comply with these standards.